Brief Introduction of NdFeB Magnetic Materials

NdFeB permanent magnets are the strongest currently commercially available magnets. They have up to ten times higher energy densities in comparison to ferrites. The excellent magnetic properties of this material are due to the strongly magnetic matrix phase Nd₂Fe₁₄B with very high saturation polarization and high magnetic anisotropy. NdFeB magnets are commonly used in automotive applications, linear or servo motors, industrial applications and aviation.

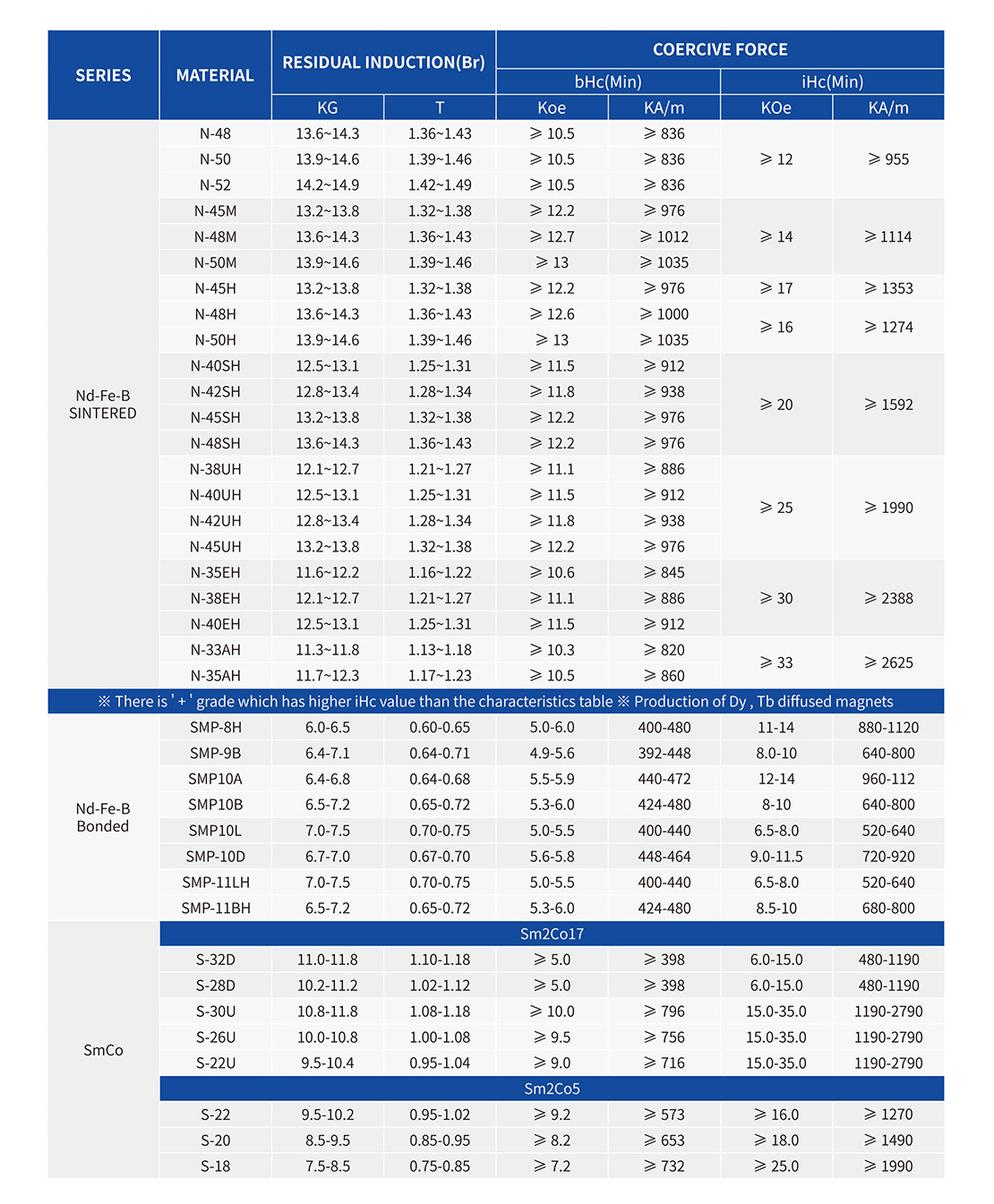

Magnetic Material Properties Table

(Nd-Fe-B、SmCo)Standard Material performance Rare Earth Magnets (Nd-Fe-B, SmCo)

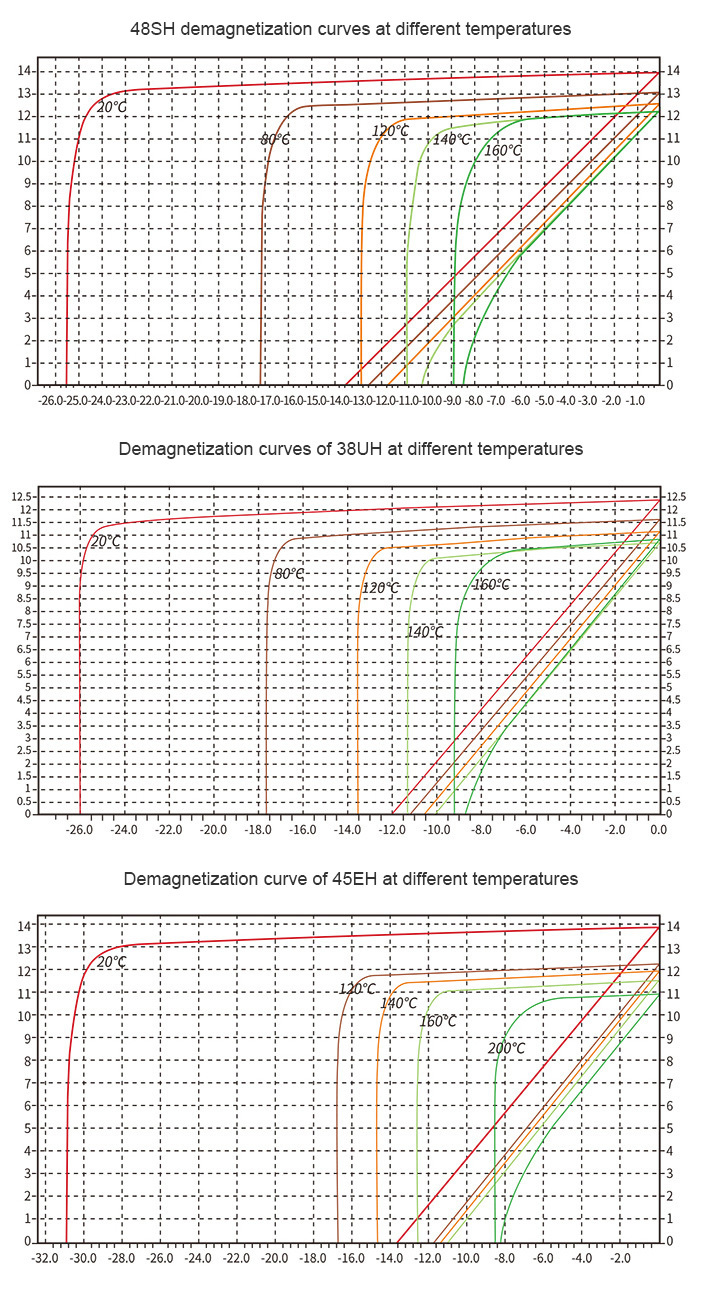

Demagnetization curve

Demagnetization curve of iron boron magnet (heavy rare earth diffusion process)

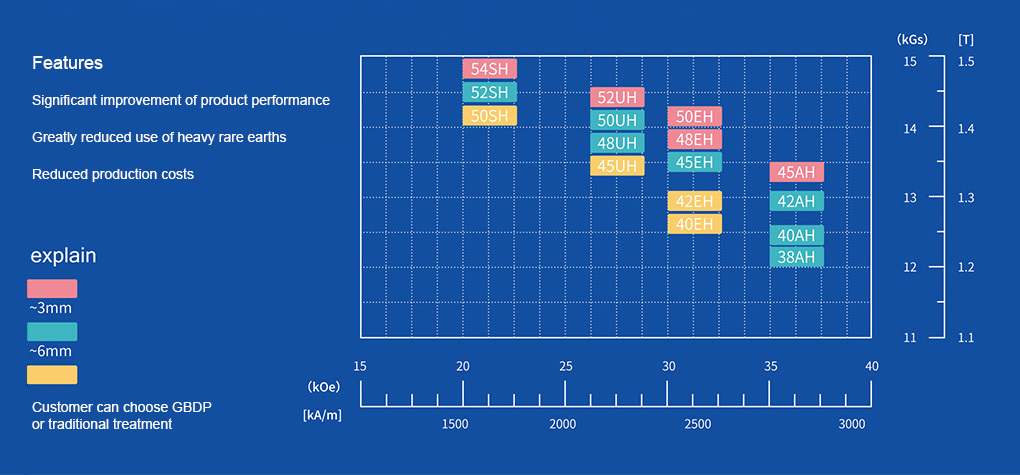

Grain boundary diffusion technology performance

Traditional sintering process grade table

| Grade | Nomal | M | H | SH | UH | EH | AH | |

|

Br Reference (KG) |

14.2~14.9 | N-52 | N-52M | |||||

| 13.9~14.6 | N-50 | N-50M | N-50H | |||||

| 13.6~14.3 | N-48 | N-48M | N-48H | N-48SH | ||||

| 13.2~13.8 | N-45 | N-45M | N-45H | N-45SH | N-45UH | |||

| 12.8~13.4 | N-42 | N-42M | N-42H | N-42SH | N-42UH | N-42EH | ||

| 12.5~13.1 | N-40 | N-40M | N-40H | N-40SH | N-40UH | N-40EH | N-40AH | |

| 12.1~12.7 | N-38 | N-38M | N-38H | N-38SH | N-38UH | N-38EH | N-38AH | |

| 11.6~12.2 | N-35 | N-35M | N-35H | N-35SH | N-35UH | N-35EH | N-35AH | |

| 11.3~11.8 | N-33 | N-33M | N-33H | N-33SH | N-33UH | N-33EH | N-33AH | |

| 11.0~11.4 | N-30 | N-30M | N-30H | N-30SH | N-30UH | N-30EH | N-30AH | |

| ≥ 12 | ≥ 14 | ≥ 17 | ≥20 | ≥25 | ≥30 | ≥ 33 | ||

| IHc Reference(kOe) | ||||||||

Grain Boundary Diffusion Process Grade Table

| Grade | Nomal | M | H | SH | UH | EH | AH | |

|

Br Reference (KG) |

14.2~14.9 | N-52 | N-52M | |||||

| 13.9~14.6 | N-50 | N-50M | N-50H | |||||

| 13.6~14.3 | N-48 | N-48M | N-48H | N-48SH | ||||

| 13.2~13.8 | N-45 | N-45M | N-45H | N-45SH | N-45UH | |||

| 12.8~13.4 | N-42 | N-42M | N-42H | N-42SH | N-42UH | N-42EH | ||

| 12.5~13.1 | N-40 | N-40M | N-40H | N-40SH | N-40UH | N-40EH | N-40AH | |

| 12.1~12.7 | N-38 | N-38M | N-38H | N-38SH | N-38UH | N-38EH | N-38AH | |

| 11.6~12.2 | N-35 | N-35M | N-35H | N-35SH | N-35UH | N-35EH | N-35AH | |

| 11.3~11.8 | N-33 | N-33M | N-33H | N-33SH | N-33UH | N-33EH | N-33AH | |

| 11.0~11.4 | N-30 | N-30M | N-30H | N-30SH | N-30UH | N-30EH | N-30AH | |

| ≥ 12 | ≥ 14 | ≥ 17 | ≥20 | ≥25 | ≥30 | ≥ 33 | ||

| IHc Reference(kOe) | ||||||||

Technical index of surface treatment

Magnetic property parameters and conversion table

| Unit and symbol | International Unit | Unit conversion table |

| Flux density B | T (Tesla) | 1T =1Vs/ m2= 10kGs |

| Polarization J | T (Tesla) | 1T =1Vs/ m2= 10kGs |

| Magnetic field H | A/m | 1kA/m3= 4πOe ≈ 12.570e |

| Energy density (BH) m | J/m3 | 1kJ/m3=0.126MGOe |

| Magnetic flux Ø | Wb(Weber) | 1Wb = 1Vs = 108Mx |

Surface treatment index

| Properties/Coatings | phosphating | zinc spray | Epoxy Coating | Ni/Ni Plating |

| Color | Grey | White | Black | Silver |

| Thickness (um) | <3 | 10-30 | 10-30 | 10-20 |

| PCT | -- | 12 hours | 48 hours | 48 hours |

| Salt spray test | 1 hour | 24 hours | 96 hours | 24 hours |

| Working temperature | -- | <200 ℃ | <200 ℃ | <200 ℃ |

Heavy rare earth diffusion process

Product application field

Elevators

Cars

Mobile Phones

Medical applications

Household appliances

Fan

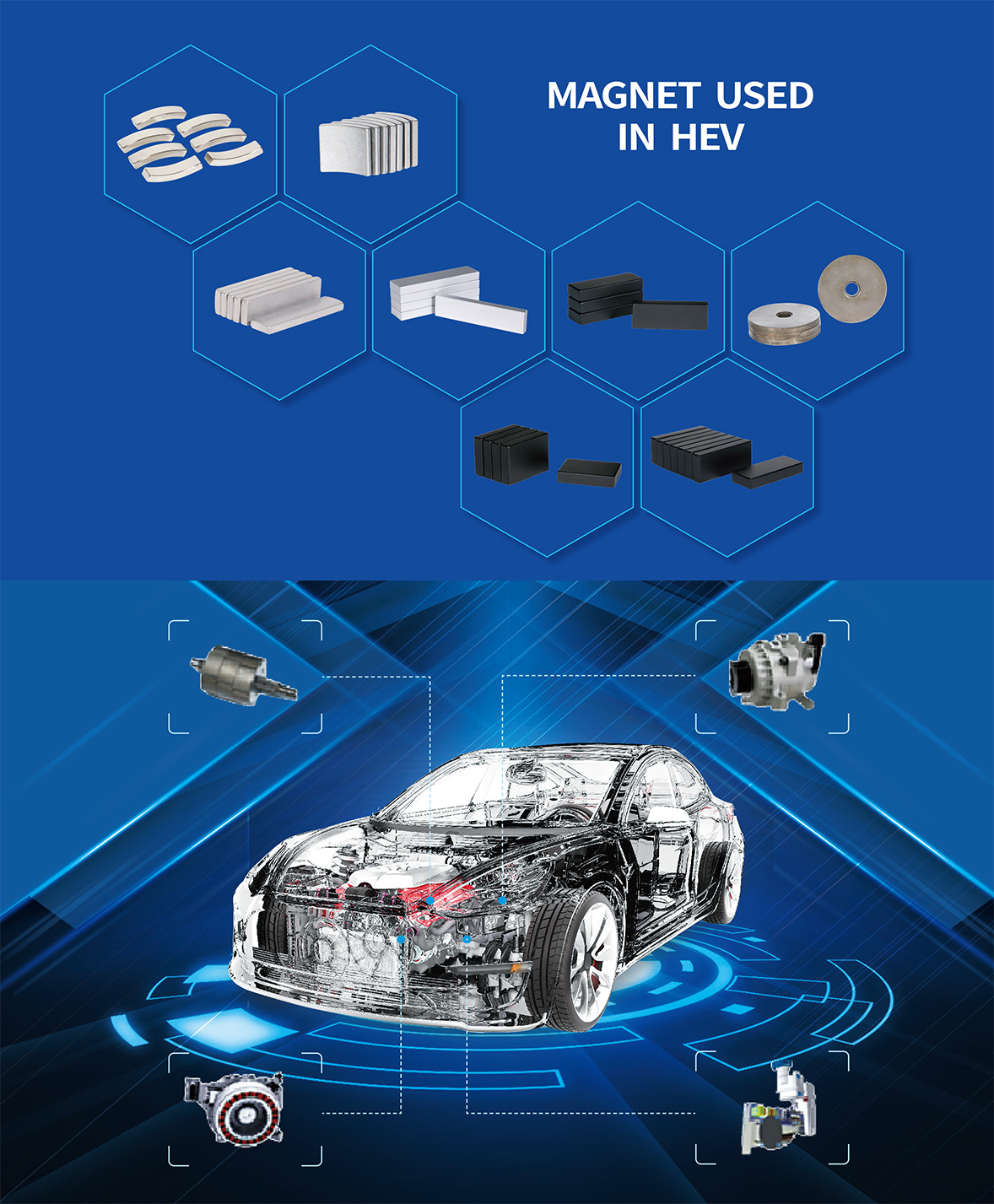

HEV USED